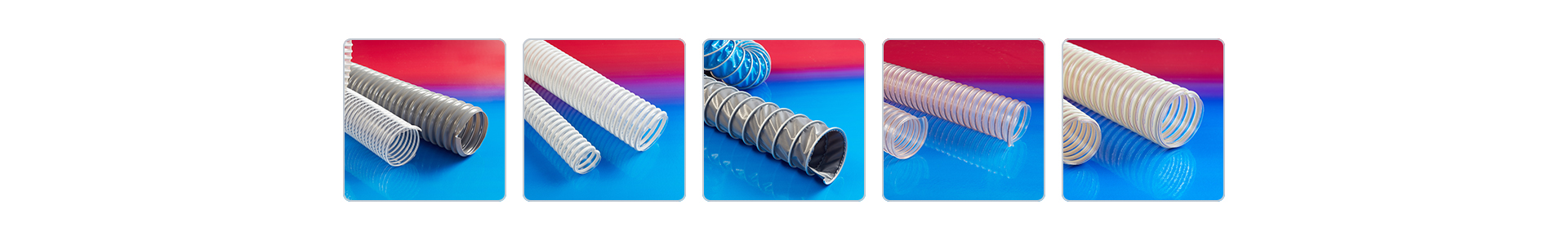

Application: High wear-resistant hose LKE590 is often used for anti-wear protection, suction and transportation, high flow rate of abrasive solids, such as sand, gravel, gravel, broken glass and debris; dry and liquid media, underground transportation ; Conveying pipes in glass manufacturing plants, docks, steel mills, quarries, shipyards, cement plants, etc., are used as durable protective pipes. It is suitable for sand suction and sand blasting machinery in mines, sand mining and sludge transportation of sand dredgers, and suction and transportation occasions with high wear resistance requirements.

Attributes: high wear resistance protection, with lower reinforced metal wire and narrow tilt (abrasion resistance is 2.5~5 times higher than most rubber materials, and 6-8 times higher than soft PVC); the interior is smooth, allowing objects in the tube to flow Smoother, resistant to high pressure, vacuum and compression, high axial strength, high tensile strength and tear strength;

Material: inner rubber: polyurethane synthetic rubber; outer rubber: rubber; spiral steel wire: elastic steel wire;

Temperature range: about -15°C to 125°C, up to 150°C in a short time

Specifications:

|

Inner diameter of hose |

wall thickness |

O.D |

工作 |

爆破 |

弯曲 |

参考 |

|||||

|

HOSE I.D. |

最小(xiǎo) |

最大 |

最小(xiǎo) |

最大 |

最小(xiǎo) |

最大 |

压力 |

压力 |

半径 |

重量 |

|

|

min |

max |

min |

max |

min |

max |

W.P. |

B.P. |

B.P. |

kg |

||

|

in |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

bar |

bar |

mm |

/m |

|

1/2″ |

13 |

12.4 |

13.5 |

4.5 |

5.5 |

22 |

24 |

10 |

30 |

125 |

0.4 |

|

5/8″ |

16 |

15.6 |

16.7 |

4.5 |

5.5 |

25 |

27 |

10 |

30 |

125 |

0.5 |

|

3/4″ |

19 |

18.2 |

19.8 |

4.5 |

5.5 |

28 |

30 |

10 |

30 |

150 |

0.6 |

|

1″ |

25 |

24.6 |

26.2 |

4.5 |

5.5 |

34 |

36 |

10 |

30 |

150 |

0.79 |

|

1-1/4″ |

32 |

32 |

33 |

4.5 |

5.5 |

41 |

43 |

10 |

30 |

200 |

0.97 |

|

1-1/2″ |

38 |

37 |

39 |

5 |

6 |

48 |

50 |

10 |

30 |

250 |

1.4 |

|

1-3/4″ |

45 |

44 |

46 |

5 |

6 |

55 |

57 |

10 |

30 |

300 |

1.5 |

|

2″ |

51 |

50 |

52 |

5 |

6 |

61 |

63 |

10 |

30 |

300 |

1.81 |

|

2-1/2″ |

64 |

63 |

65 |

6 |

7 |

76 |

78 |

10 |

30 |

350 |

2.28 |

|

3 |

76 |

75 |

77 |

7.5 |

8.5 |

91 |

93 |

10 |

30 |

460 |

2.93 |

|

3-1/2″ |

89 |

88 |

90 |

7.5 |

8.5 |

104 |

106 |

10 |

30 |

530 |

3.5 |

|

4″ |

102 |

101 |

103 |

8.5 |

9.5 |

119 |

121 |

10 |

30 |

600 |

5 |

|

4-1/2″ |

114 |

113 |

115 |

8.5 |

9.5 |

131 |

133 |

10 |

30 |

900 |

6 |

|

5″ |

127 |

126 |

128 |

10 |

11 |

147 |

149 |

10 |

30 |

900 |

6.6 |

|

5-1/2″ |

140 |

139 |

141 |

10.4 |

11 |

160 |

162 |

10 |

30 |

1100 |

7.15 |

|

6″ |

152 |

151 |

153 |

10 |

11 |

172 |

174 |

10 |

30 |

1200 |

7.8 |

|

6-1/2″ |

165 |

164 |

166 |

10 |

11 |

185 |

187 |

10 |

30 |

1320 |

8.45 |

|

8″ |

203 |

202 |

204 |

12 |

13 |

227 |

229 |

10 |

30 |

1500 |

10.4 |

|

10″ |

254 |

253 |

255 |

12 |

13 |

278 |

280 |

10 |

30 |

2000 |

13 |

|

12″ |

305 |

304 |

306 |

13 |

14 |

331 |

333 |

10 |

30 |

2500 |

16.2 |

|

14″ |

356 |

355 |

357 |

13 |

14 |

382 |

384 |

10 |

30 |

2500 |

18.9 |

|

16″ |

406 |

405 |

407 |

13 |

14 |

432 |

434 |

10 |

30 |

2500 |

21.6 |

官方公众号

官方公众号