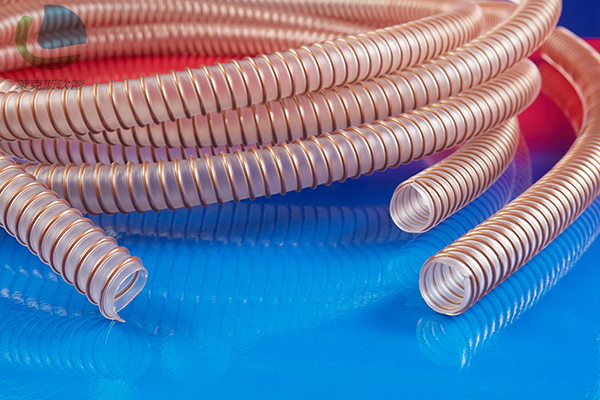

PU wear-resistant steel wire tube LKE00551

Application: PU wear-resistant steel wire tube LKE00531 is used as a wear-resistant conveying hose for heavy materials. It is generally used in suction occasions. Particularly suitable for abrasive solids, such as dust, powder, fibers and debris, active media such as oil vapor and welding fumes, industrial dust removal and suction. Mainly used for ventilation and dust collection in dusty production environments such as woodworking machinery, ceramic machinery, and cement workshops.

Attributes: wear-resistant protection. High tensile strength. Strong tear resistance; anti-microbial and hydrolysis. Excellent mineral oil resistance and chemical resistance. UV and ozone resistance. Low temperature resistance. Small bending radius. Not easy to kink. Does not contain softener and halogen. Gas and liquid do not leak. Complies with RoHS regulations. Grounding through spiral wire can discharge static electricity. Comply with EN45545 fire protection standard.

It can be customized into food-grade hoses. The pipe wall complies with: FDA 21 CFR 177.2600 and 178.2010. EC regulations 2002/72/EC including revised regulations 2007/19/EC The testing agency certified conforms to EC 2002/72/EC regulations. Including revised 2007/19/EC.

Structure: with copper-plated plastic coated steel wire spiral reinforcement. Ribbon extrusion. Wall thickness is about 1.0 mm

Material: pipe wall: special polyether-polyurethane. Spiral wire: elastic steel wire

Temperature range: about -40°C to +100°C, up to +125°C in a short time

Specifications:

|

I.D

|

O.D |

OP.pressure |

Bend radius (middle of hose) |

Weight |

Length |

Item NO |

|

|

positive pressure |

negative pressure |

||||||

|

mm |

mm |

bar |

bar |

mm |

Kg/m |

m |

|

|

20 |

25 |

1.8 |

0.50 |

25 |

0.13 |

20 |

LKE-551-0020 |

|

25 |

32 |

1.6 |

0.36 |

32 |

0.17 |

20 |

LKE-551-0025 |

|

30 |

37 |

1.345 |

0.34 |

37 |

0.2 0 |

20 |

LKE-551-0030 |

|

32 |

39 |

1.26 |

0.34 |

39 |

0.21 |

20 |

LKE-551-0032 |

|

38 |

45 |

1.06 |

0.32 |

45 |

0.25 |

20 |

LKE-551-0038 |

|

40 |

47 |

1.015 |

0.3 |

47 |

0.28 |

20 |

LKE-551-0040 |

|

45 |

52 |

0.9 |

0.285 |

52 |

0.31 |

20 |

LKE-551-0045 |

|

50 |

58 |

0.815 |

0.26 |

58 |

0.36 |

20 |

LKE-551-0050 |

|

51 |

59 |

0.8 |

0.26 |

59 |

0.37 |

20 |

LKE-551-0051 |

|

60 |

68 |

0.68 |

0.21 |

68 |

0.43 |

20 |

LKE-551-0060 |

|

63 |

71 |

0.645 |

0.195 |

71 |

0.45 |

20 |

LKE-551-0063 |

|

65 |

73 |

0.63 |

0.18 |

73 |

0.47 |

20 |

LKE-551-0065 |

|

70 |

78 |

0.585 |

0.15 |

78 |

0.5 0 |

20 |

LKE-551-0070 |

|

75 |

83 |

0.545 |

0.14 |

83 |

0.53 |

20 |

LKE-551-0075 |

|

80 |

88 |

0.51 |

0.13 |

88 |

0.57 |

20 |

LKE-551-0080 |

|

90 |

98 |

0.455 |

0.115 |

98 |

0.63 |

20 |

LKE-551-0090 |

|

100 |

108 |

0.41 |

0.09 |

108 |

0.66 |

20 |

LKE-551-0100 |

|

102 |

110 |

0.4 |

0.09 |

110 |

0.68 |

20 |

LKE-551-0102 |

|

110 |

118 |

0.375 |

0.08 |

118 |

0.73 |

20 |

LKE-551-0110 |

|

115 |

123 |

0.355 |

0.08 |

123 |

0.76 |

20 |

LKE-551-0115 |

|

120 |

128 |

0.34 |

0.075 |

128 |

0.79 |

20 |

LKE-551-0120 |

|

125 |

133 |

0.33 |

0.06 |

133 |

0.82 |

20 |

LKE-551-0125 |

|

127 |

135 |

0.325 |

0.06 |

135 |

0.83 |

20 |

LKE-551-0127 |

|

130 |

138 |

0.315 |

0.06 |

138 |

0.85 |

20 |

LKE-551-0130 |

|

140 |

148 |

0.295 |

0.06 |

148 |

0.92 |

20 |

LKE-551-0140 |

|

150 |

158 |

0.275 |

0.055 |

158 |

0.98 |

20 |

LKE-551-0150 |

|

152 |

160 |

0.27 |

0.055 |

160 |

0.99 |

20 |

LKE-551-0152 |

|

160 |

168 |

0.255 |

0.05 |

168 |

1.04 |

20 |

LKE-551-0160 |

|

170 |

178 |

0.24 |

0.045 |

178 |

1.11 |

20 |

LKE-551-0170 |

|

175 |

183 |

0.235 |

0.04 |

183 |

1.14 |

20 |

LKE-551-0175 |

|

180 |

188 |

0.23 |

0.04 |

188 |

1.17 |

20 |

LKE-551-0180 |

|

200 |

208 |

0.205 |

0.04 |

208 |

1.54 |

20 |

LKE-551-0200 |

|

203 |

211 |

0.205 |

0.04 |

211 |

1.57 |

20 |

LKE-551-0203 |

|

225 |

233 |

0.18 |

0.03 |

233 |

1.75 |

20 |

LKE-551-0225 |

|

250 |

258 |

0.165 |

0.015 |

258 |

1.90 |

20 |

LKE-551-0250 |

官方公众号

官方公众号