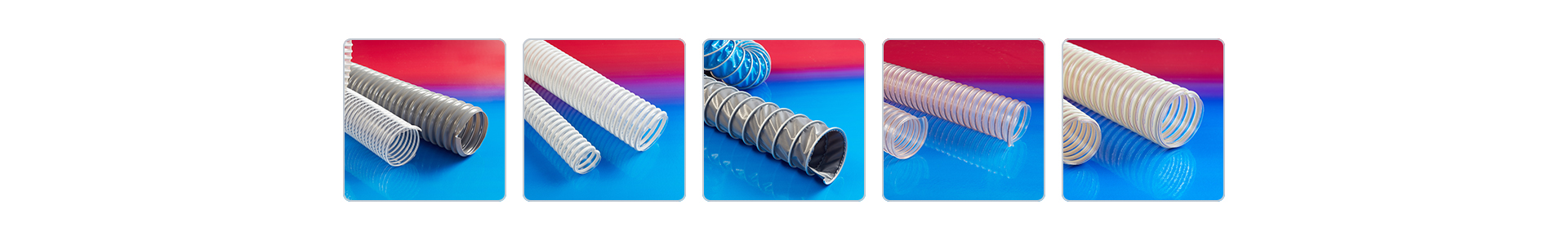

Acid and alkali resistant hose LKE332

Application: suitable for solid with strong wear force, such as dust, powder, fiber, debris and particles, corrosive gas and liquid media.

Vacuum Cleaning Machine, Conveyor System, Hair Blow and Compressor, Chemical Industry,

FDA 21 CFR 177.1520 (C) 3.2A, EC Guideline 2002/72/EC Incl. Amendment 2005/79/EC, German Guidline III BFR (see Chapt. 14.5). No odor, no taste, good resistance to mineral oil, good resistance to alkali metal and acid, excellent chemical resistance, small bending radius, not easy to knot, telescopic, smooth inside, optimize the flow characteristics; No softener and halogen, no leakage of gas and liquid, in accordance with RoHS regulations, can discharge static electricity, through the spiral wire grounding.

Structure: Spiral plastic reinforcement is firmly implanted into the wall of the tube to optimize the external fluidity. The wall thickness is about 0.8mm

Material: Tube wall material: polyethylene, spiral wire: spiral plastic bar temperature about -35°C to +100°C

Product specifications:

|

I.D |

O.D |

OP.pressure |

Bend radius ( Middle of hose) |

Weight |

Length |

Item NO |

|

|

positive Pressure |

Vacuum |

||||||

|

mm |

mm |

bar |

bar |

mm |

Kg/m |

m |

|

|

28 |

34 |

1.04 |

0.54 |

34 |

0.25 |

10 |

LKE-332-0028 |

|

30 |

37 |

0.98 |

0.52 |

37 |

0.21 |

10 |

LKE-332-0030 |

|

32 |

39 |

0.92 |

0.505 |

39 |

0.23 |

10 |

LKE-332-0032 |

|

35 |

42 |

0.84 |

0.495 |

42 |

0.24 |

10 |

LKE-332-0035 |

|

38 |

45 |

0.775 |

0.475 |

45 |

0.26 |

10 |

LKE-332-0038 |

|

40 |

47 |

0.74 |

0.46 |

47 |

0.28 |

10 |

LKE-332-0040 |

|

45 |

52 |

0.66 |

0.43 |

52 |

0.31 |

10 |

LKE-332-0045 |

|

50 |

57 |

0.595 |

0.395 |

57 |

0.34 |

10 |

LKE-332-0050 |

|

55 |

62 |

0.54 |

0.35 |

62 |

0.37 |

10 |

LKE-332-0055 |

|

60 |

67 |

0.495 |

0.32 |

67 |

0.4 |

10 |

LKE-332-0060 |

|

65 |

72 |

0.46 |

0.275 |

72 |

0.44 |

10 |

LKE-332-0065 |

|

70 |

79 |

0.425 |

0.23 |

79 |

0.56 |

10 |

LKE-332-0070 |

|

75 |

84 |

0.395 |

0.21 |

84 |

0.6 |

10 |

LKE-332-0075- |

|

80 |

89 |

0.375 |

0.2 |

89 |

0.64 |

10 |

LKE-332-0080 |

|

90 |

99 |

0.33 |

0.17 |

99 |

0.71 |

10 |

LKE-332-0090 |

|

100 |

109 |

0.3 |

0.135 |

109 |

0.79 |

10 |

LKE-332-0100 |

|

110 |

119 |

0.27 |

0.12 |

119 |

0.86 |

10 |

LKE-332-0110 |

|

115 |

124 |

0.26 |

0.115 |

124 |

0.9 |

10 |

LKE-332-0115 |

|

120 |

129 |

0.25 |

0.115 |

129 |

0.94 |

10 |

LKE-332-0120 |

|

125 |

134 |

0.24 |

0.09 |

134 |

0.98 |

10 |

LKE-332-0125 |

|

130 |

139 |

0.23 |

0.09 |

139 |

1.03 |

10 |

LKE-332-0130 |

|

140 |

149 |

0.215 |

0.09 |

149 |

1.1 |

10 |

LKE-332-0140 |

|

150 |

159 |

0.2 |

0.09 |

159 |

1.16 |

10 |

LKE-332-0150 |

|

160 |

169 |

0.185 |

0.075 |

169 |

1.24 |

10 |

LKE-332-0160 |

|

175 |

184 |

0.17 |

0.06 |

184 |

1.36 |

10 |

LKE-332-0175 |

|

180 |

189 |

0.165 |

0.06 |

189 |

1.4 |

10 |

LKE-332-0180 |

|

200 |

210 |

0.15 |

0.06 |

210 |

1.55 |

10 |

LKE-332-0200 |

|

225 |

235 |

0.135 |

0.04 |

235 |

1.74 |

10 |

LKE-332-0225 |

|

250 |

260 |

0.12 |

0.025 |

260 |

1.92 |

10 |

LKE-332-0250 |

|

275 |

285 |

0.11 |

0.02 |

285 |

2.09 |

10 |

LKE-332-0275 |

|

280 |

290 |

0.105 |

0.02 |

290 |

2.13 |

10 |

LKE-332-0280 |

|

300 |

310 |

0.1 |

0.02 |

310 |

2.27 |

10 |

LKE-332-0300 |

官方公众号

官方公众号