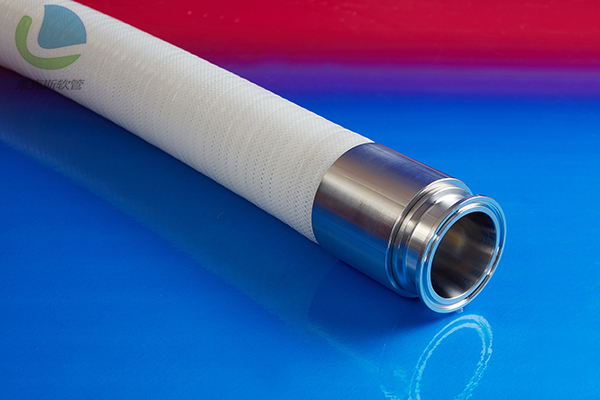

Sanitary silicone hose LKE638

The sanitary silicone hose LKE638 is reinforced by 316 stainless steel. It can withstand large negative pressure. It is an ideal suction sanitary hose. The spiral silicone hose provides a smaller bending radius. It is easy to operate and use. Suitable for pharmaceutical, Industrial applications such as biomedical, cosmetics and food processing.

Product Features:

Sanitary platinum vulcanized silicone hose has a low internal rubber decomposition rate. It is produced in a certified clean room. It is widely used in biomedical rooms. Ultra-pure liquid transmission. Cell culture. Medicine transportation. Liquid filling and transmission. Peristaltic pumps. Veterinary drugs Pharmaceutical. Food and beverage transmission. After a lot of physical, chemical and biological tests, it has reached the standards of USP Class VI, FDA CFR 177.2600, ISO 10993, European Pharmacopoeia 3.1.9 and 3A.

Product Features:

Four layers of polyester fabric. Steel wire spiral reinforcement. Conforms to U.S. FDA-level standards; the inner and outer walls of the hose are smooth. Easy to clean; can be used for complete vacuum; resistance to pressure rupture. Resistance to kinks; durable. Withstand strong pressure; translucent allows visual monitoring of the medium flow.

Normal operating temperature range: from -73.3° C to 204.4° C;

It can be cleared by CIP, SIP or ray or high pressure;

Resistant to compression, chemicals, ozone, radiation, humidity and environmental erosion;

Does not produce any odor or taste to the solution medium;

Produced in a strictly controlled environment following GMP requirements;

To keep clean, the hose is sealed in a transparent polyethylene bag;

90 or 45 degree corner thermoforming and coiled hose can be produced according to requirements;

Specify length, size and packaging can be produced according to requirements

Withhold the sanitary quick coupling as required. SMS standard. DIN standard and other threaded joints. Can be equipped with hose clamps. Material 316L;

Specifications:

|

I.D mm |

O.D mm |

Thickness mm |

Burst pressure Kg |

Weight g/m |

Bend radius mm |

Length m |

|

±0.50 |

|

+1 / -0.5 |

|

±5% |

|

|

|

6 |

19 |

6.50 |

63 |

44 |

43 |

10 |

|

8 |

21 |

6.50 |

58 |

128 |

46 |

10 |

|

9 |

22 |

6.50 |

56 |

170 |

47 |

10 |

|

10 |

23 |

6.50 |

54 |

212 |

49 |

10 |

|

13 |

26 |

6.50 |

49 |

338 |

54 |

10 |

|

15 |

28 |

6.50 |

47 |

422 |

58 |

10 |

|

16 |

29 |

6.50 |

45 |

464 |

59 |

10 |

|

18 |

31 |

6.50 |

43 |

548 |

63 |

10 |

|

19 |

32 |

6.50 |

42 |

590 |

66 |

10 |

|

20 |

33 |

6.50 |

41 |

632- |

68 |

10 |

|

22 |

35 |

6.50 |

40 |

716 |

72 |

10 |

|

25 |

38 |

6.50 |

37 |

842 |

80 |

10 |

|

28 |

41 |

6.50 |

35 |

968 |

88 |

10 |

|

30 |

43 |

6.50 |

34 |

1052 |

94 |

10 |

|

32 |

45 |

6.50 |

33 |

1136 |

100 |

10 |

|

34 |

47 |

6.50 |

32 |

1220 |

107 |

10 |

|

35 |

48 |

6.50 |

31 |

1262 |

110 |

10 |

|

38 |

52 |

7.00 |

30 |

1388 |

121 |

10 |

|

40 |

54 |

7.00 |

29 |

1472 |

129 |

10 |

|

42 |

56 |

7.00 |

28 |

1556 |

138 |

10 |

|

43 |

57 |

7.00 |

27 |

1598 |

143 |

10 |

|

44 |

58 |

7.00 |

27 |

1640 |

147 |

10 |

|

45 |

59 |

7.00 |

27 |

1682 |

152 |

10 |

|

48 |

62 |

7.00 |

25 |

1808 |

168 |

10 |

|

50 |

64 |

7.00 |

25 |

1892 |

179 |

10 |

|

51 |

65 |

7.00 |

24 |

1934 |

185 |

10 |

|

52 |

66 |

7.00 |

24 |

1976 |

191 |

10 |

|

53 |

67 |

7.00 |

24 |

2018 |

197 |

10 |

|

55 |

69 |

7.00 |

23 |

2102 |

210 |

10 |

|

57 |

71 |

7.00 |

22 |

2186 |

224 |

10 |

|

60 |

74 |

7.00 |

21 |

2312 |

247 |

10 |

|

62 |

76 |

7.00 |

21 |

2396 |

264 |

10 |

|

63 |

77 |

7.00 |

20 |

2438 |

273 |

10 |

|

65 |

79 |

7.00 |

20 |

2522 |

291 |

10 |

|

68 |

82 |

7.00 |

19 |

2648 |

293 |

10 |

|

70 |

84 |

7.00 |

19 |

2732 |

295 |

10 |

|

75 |

89 |

7.00 |

17 |

2942 |

315 |

10 |

|

76 |

90 |

7.00 |

17 |

2984 |

318 |

10 |

|

80 |

94 |

7.00 |

16 |

3152 |

331 |

10 |

|

83 |

97 |

7.00 |

15 |

3278 |

338 |

10 |

|

85 |

99 |

7.00 |

15 |

3362 |

342 |

10 |

|

87 |

101 |

7.00 |

15 |

3446 |

345 |

10 |

|

90 |

104 |

7.00 |

14 |

3572 |

349 |

10 |

|

95 |

109 |

7.00 |

13 |

3782 |

368 |

10 |

|

100 |

114 |

7.00 |

12 |

3992 |

423 |

10 |

|

102 |

116 |

7.00 |

12 |

4076 |

431 |

10 |

官方公众号

官方公众号