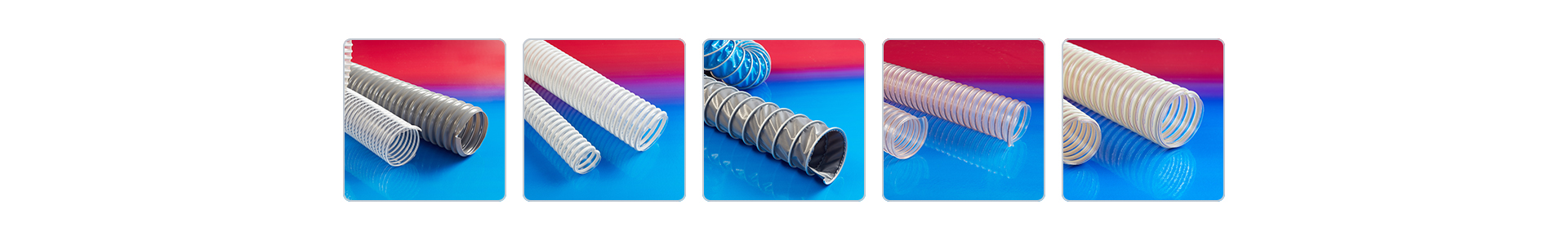

PU steel wire hose LKE508

Application: PU steel wire hose LKE508. Usually used in wear-out suction situation. It is especially suitable for wearing solid particles. Such as dust, powder, fiber, debris and granular, gaseous and liquid media. Industrial dust removal and suction. Industrial vacuum suction. Suction of paper or fabric fibers. As an anti-wear protective tube.

Properties: High wear resistance protection (wear resistance is 6 times higher than most rubber materials. Soft PVC 8 times higher). Smooth interior. Low wind resistance. Make the flow in the hose smoother. Telescopic; High tensile strength. and tear strength. Good mineral oil resistance and chemical resistance; Good uv and ozone resistance and low temperature scalability. Small bending radius. Not easy to knot. Free of softeners and halogens; Gases and liquids do not leak. The flame retardant meets UL94-HB standard. Comply with RoHS regulations. Static electricity can be discharged by grounding through screw wire.

Structure: Spiral elastic steel wire is firmly implanted into the pipe wall. The wall is 0.9mm thick

Material: Pipe wall: Special polyether-polyurethane pre-pur. Spiral wire: elastic steel wire

Temperature range: approx. -40°C to +125°C. Short duration approx. +150°C

Product specifications:

I.D

O.D

OP.pressure

Bend radius

Weight

Length

Item NO

Positive

pressure

negative

pressure

mm

mm

bar

bar

mm

Kg/m

m

25

32

2.69

0.495

35

0.2

20

LKE-508-0025

30

38

2.26

0.475

42

0.26

20

LKE-508-0030

32

40

2.12

0.46

44

0.28

20

LKE-508-0032

35

43

1.94

0.44

47

0.3

20

LKE-508-0035

38

46

1.795

0.43

51

0.32

20

LKE-508-0038

40

48

1.71

0.42

53

0.34

20

LKE-508-0040

45

53

1.525

0.385

58

0.38

20

LKE-508-0045

50

58

1.37

0.365

64

0.41

20

LKE-508-0050

55

63

1.255

0.33

69

0.45

LKE-508-0055

60

68

1.15

0.285

75

0.49

LKE-508-0060

65

73

1.06

0.255

80

0.53

LKE-508-0065

70

79

0.99

0.21

87

0.59

LKE-508-0070

75

84

0.92

0.195

92

0.64

20

LKE-508-0075

80

89

0.86

0.175

98

0.68

LKE-508-0080

90

99

0.77

0.155

109

0.75

20

LKE-508-0090

100

109

0.69

0.12

120

0.97

LKE-508-0100

102

111

0.68

0.12

122

0.99

20

LKE-508-0102

110

119

0.63

0.11

131

1.06

LKE-508-0110

115

124

0.605

0.105

136

1.11

20

LKE-508-0115

120

129

0.58

0.105

142

1.16

LKE-508-0120

125

134

0.56

0.085

147

1.2

LKE-508-0125

127

136

0.545

0.085

148

1.22

20

LKE-508-0127

130

139

0.535

0.085

153

1.25

20

LKE-508-0130

140

149

0.495

0.085

164

1.34

20

LKE-508-0140

150

159

0.46

0.075

175

1.52

LKE-508-0150

160

169

0.435

0.065

186

1.61

20

LKE-508-0160

170

179

0.41

0.065

195

1.71

20

LKE-508-0170

175

184

0.4

0.055

202

1.76

20

LKE-508-0175

180

189

0.385

0.055

208

1.81

20

LKE-508-0180

200

209

0.35

0.055

230

2

LKE-508-0200

203

212

0.345

0.055

233

2.03

20

LKE-508-0203

225

234

0.31

0.04

257

2.16

20

LKE-508-0225

250

259

0.28

0.02

285

2.39

20

LKE-508-0250

275

284

0.255

0.02

312

2.63

LKE-508-0275

280

289

0.25

0.02

318

2.67

20

LKE-508-0280

300

309

0.23

0.02

340

2.86

LKE-508-0300

315

324

0.22

0.02

356

3

20

LKE-508-0315

320

329

0.215

0.02

362

3.05

20

LKE-508-0320

325

334

0.215

0.015

367

3.1

LKE-508-0325

350

359

0.2

0.015

395

3.33

LKE-508-0350

375

384

0.185

0.01

424

3.9

20

LKE-508-0375

400

409

0.17

0.01

450

4.27

LKE-508-0400

450

459

0.155

0.01

508

4.8

20

LKE-508-0450

500

509

0.14

0.01

565

5.33

20

LKE-508-0500

官方公众号

官方公众号